Vicnyl庐 HTPA materials offer excellent overall performance.聽

(1) Outstanding high temperature performance聽

High melting point (Tm up to 325鈩?聽

High聽transition temperature of vitrification聽(Tg up to 125鈩 in dry state)

High heat distortion temperature (HDT up to 295鈩?聽

(2) Less affected by humid environment or even hot water聽

High mechanical performance retention rate

Good dimensional stability聽

(3) Suitable for surface mounting by聽lead-free reflow soldering

(4) Excellent chemical resistance

(5) Excellent electrical performance聽

(6) Excellent formability, suitable for rapid thin-wall forming

Vicnyl庐 HTPA is available in five series.聽

(1) Vicnyl庐 HTPA 鈥?鈥滭/span>

聽鈥 Vicnyl庐 3 Series is a reinforced semi-aromatic polyamide with high glass fiber content, which has聽high strength, high rigidity, impact resistance and good appearance. Its performance is less affected by humidity and is suitable for structural parts.

(2) Vicnyl庐 HTPA 鈥?鈥滭/span>

聽鈥 Vicnyl庐 4 Series is a high performance semi-aromatic polyamide that has low water absorption, good chemical resistance, electrical properties and dimensional stability.聽

(3) Vicnyl庐 HTPA 鈥?鈥澛燑/span>

鈥 Vicnyl庐 5 Series is a high performance semi-aromatic polyamide that has low water absorption, low warpage, good chemical resistance and dimensional stability.聽

(4) Vicnyl庐 HTPA 鈥?1鈥澛燑/span>

鈥 Vicnyl庐 61 Series is a bio-based, high performance semi-aromatic polyamide with extremely low water absorption, good resistance to hydrolysis and alcoholysis, chemical resistance and dimensional stability.

聽(5) Vicnyl庐 HTPA 鈥?鈥滭/span>

鈥 Vicnyl庐 7 Series is a bio-based, high performance semi-aromatic polyamide with extremely low water absorption, excellent resistance to hydrolysis and alcoholysis, chemical resistance and dimensional stability.

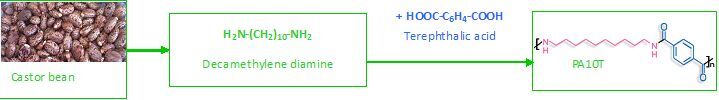

The Vicnyl庐 61 and 7 series are based on poly (decamethylene terephthalamide) (Vicnyl庐 PA10T), one of the monomers, the diamine (account for about 50wt% in the weight of total monomer), is derived from renewable resources 鈥 ramie beans.

The bio-carbon content of Vicnyl庐 PA10T material is between 40 wt% and 60 wt%.

Compared to other high temperature resistant nylon materials, the advantages of Vicnyl庐 PA10T are:

(1) The water absorption rate is much lower than that of PA46, PA4T and PA6T, resulting in higher dimensional stability, higher strength and rigidity retention in humid environments;

(2) Better hydrolysis and alcoholysis than PA46, PA4T and PA6T

(3) Better resistance to reflow soldering than PA46, PA4T and PA6T (MSL 1)

(4) Better color stability

The main application of Vicnyl庐 HTPA

(1) Application of Vicnyl庐 PA10T on LED reflection stand

聽Maintains high whiteness and high reflectance after 3 reflow soldering, high temperature in long time and UV aging treatment

聽Water absorption is much lower than PA6T, and it has higher dimensional stability for long-term use.

聽Rapid crystallization, greatly shortens the molding cycle

Good adhesion to lead frames, encapsulating resins (silicone and epoxy)

Grades |

Description |

Vicnyl庐聽L740 WT |

40% GF and mineral co-reinforced |

Vicnyl庐聽L740C WT |

40% mineral reinforced |

Vicnyl庐聽L740HR WT |

40% mineral reinforced, higher 聽 brightness |

Vicnyl庐聽L740HL WT |

40% mineral reinforced, higher 聽 brightness |

Vicnyl庐聽L740 BK |

40% mineral reinforced |

聽

(2) Application of Vicnyl庐 PA10T on automobiles聽

Outstanding heat resistance

Water absorption is much lower than PA46, PA4T and PA6T, resulting in higher dimensional stability, higher strength and stiffness retention in wet environment

Better resistance to long-lasting coolant performance (LLC) than PA46, PA4T and PA6T

Heat-resistant parts under the hood, bearing cage, ignition coil bobbin, coolant pump, thermostat, intake manifold, etc.

聽

Grades |

Description |

Vicnyl庐聽72G35HS |

35% GF reinforced, heat stabilized, excellent resistance to LLC |

Vicnyl庐聽72G45HS |

45% GF reinforced, heat stabilized, excellent resistance to LLC |

Vicnyl庐聽72GF30HSL2 |

30% GF reinforced, wear resistant, heat stabilized |

聽

(3) Application of Vicnyl庐 HTPA on SMT connectors聽

Outstanding heat resistance

Low water absorption and high dimensional stability聽

Good resistance to reflow soldering

No 鈥渂looming鈥滭/span>

聽Good color stability

聽High fluidity for rapid thin-wall forming

Grades |

Description |

Vicnyl庐聽430 |

30% GF reinforced, UL94 HB at 0.75~3.0mm |

Vicnyl庐聽R430NH |

30% GF reinforced, free of halogen and red phosphorus, 聽 UL94 V-0 at 0.25~3.0mm |

Vicnyl庐聽R445NH |

45% GF reinforced, free of halogen and red phosphorus, UL94 V-0 at 0.25~3.0mm |

Vicnyl庐聽R430 |

30% GF reinforced, halogenated, UL94 V-0 at 0.4~3.0mm |

Vicnyl庐聽R445 |

45% GF reinforced, halogenated, UL94 V-0 at 0.4~3.0mm |

Vicnyl庐聽6130 |

30% GF reinforced, UL94 HB at 0.75~3.0mm, superbly low water absorption |

Vicnyl庐聽R6115NH |

15% GF reinforced, free of halogen and red phosphorus, UL94 V-0 at 0.2~3.0mm, superbly low water 聽 absorption, in line with MSL1 |

Vicnyl庐聽R6130NH |

30% GF reinforced, free of halogen and red phosphorus, UL94 V-0 at 0.2~3.0mm, superbly low water 聽 absorption, in line with MSL1 |

Vicnyl庐聽R6145NH |

45% GF reinforced, free of halogen and red phosphorus, 聽 UL94 V-0 at 0.2~3.0mm, superbly low water absorption, in line with MSL1 |

聽

(4) Application of Vicnyl庐 HTPA on plumbing parts聽

鈥 Passed the NSF 61 certification

鈥 Excellent long-term resistant to heat water and chloride-containing water聽

鈥 Replace metals to reduce costs

Grades |

Description |

Vicnyl庐聽32G40HR |

40% GF reinforced, NSF 61 compatible |

Vicnyl庐聽32G50HR |

50% GF reinforced, NSF 61 compatible |

Vicnyl庐聽32G60HR |

60% GF reinforced, NSF 61 compatible |

Vicnyl庐聽62G40HR |

40% GF reinforced , NSF 61 compatible, much higher retention of strength and stiffness after long term use in hot water |

Vicnyl庐聽62G50HR |

50% GF reinforced , NSF 61 compatible, much higher retention of strength and stiffness after long term use in hot water |

Vicnyl庐聽62G60HR |

60% GF reinforced , NSF 61 compatible, much higher retention of strength and stiffness after long term use in hot water |

聽

(5) Application of Vicnyl庐 HTPA in IT/OA structural framework

Outstanding heat resistance聽

Low water absorption, resulting in high dimensional stability, high strength and high stiffness retention in wet environment聽

High strength, high rigidity

High liquidity聽

Low warpage

Good appearance

Good spray performance

Grades |

Description |

Vicnyl庐聽350XF |

50% GF reinforced, UL94 HB at 0.5~3.0mm |

Vicnyl庐聽360XF |

60% GF reinforced, UL94 HB at 0.5~3.0mm |

Vicnyl庐聽65GR50NHXF |

50% GF reinforced, 聽free of halogen and red phosphorus, UL94 V-0 at 0.8mm,聽lower water 聽 absorption, higher dimensional stability and retention of strength and stiffness after long term use in humid conditions |

聽